Upgrade Guide

1. Check your version

The version of Calisto which can be used depends on the maintenance expiration date. To check your maintenance expiration date, use the menu File → License when you are logged into Calisto.

Calisto License Window. The maintenance expiration date is circled in red.

The latest version of Calisto is 2.13.

Released on June 22nd, 2023.

| Maintenance Expiration | Accessible Version |

|---|---|

| After December 9th, 2022 | 2.13 |

| Between December 18th, 2018 and December 9th, 2022 | 2.0994 |

| Between January 6th, 2016 and December 18th, 2018 | 1.493 |

| Between September 9th, 2013 and January 6th, 2016 | 1.39 |

| Between October 3rd, 2012 and September 9th, 2013 | 1.15 |

| Between June 30th, 2011 and October 3rd, 2012 | 1.099 |

| Between November 16th, 2010 and June 30th, 2011 | 1.088 |

| Between March 31st, 2010 and November 16th, 2010 | 1.077 |

| Before March 31st, 2010 | 1.066 |

2. Backup your data

IMPORTANT : Before upgrading, it is recommended to backup your data. This operation is quick, simple and it makes sure that all your data are safe during the upgrade process.

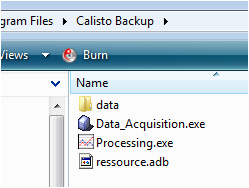

- Create a new folder, i.e. “Calisto Backup”

- Copy the following files :

- Processing.exe

- Data_Acquisition.exe

- ressource.adb

- the folder “data”

- Your data are now archived. You can proceed with the upgrade process

1/ Backup your files before upgrading

3. Upgrade Calisto

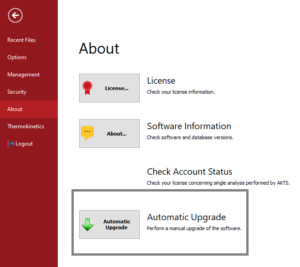

If the computer where Calisto is installed is connected to Internet (online)

In the Calisto software, go to the menu “File” – “Automatic Upgrade”. Calisto will upgrade automatically.

2/ Access to the menu Automatic Upgrade

If the computer where Calisto is installed is NOT connected to Internet (offline)

4. New functionalities

The list of the new functionalities and bug corrections are described in Calisto Data Acquisition and Processing help files.

Download Calisto Help File – English (zip, 4.56 MB)

Download Calisto Help File – French (Français) (zip, 4.62 MB)

5. Database Update

If apparatus connexion or display issues occurs after a Calisto upgrade from an anterior version to 1.096, we recommand to download the below link to patch the database. This can mainly happen to customers using regional settings with special characters such as China, Japan, Russia, etc.

Download Calisto patch (zip, 1.75 MB)