|

|

AKTS is pleased to announce the release of

AKTS-SML Software version 6

Improved Ergonomy

Improved Ergonomy

Repeated Use Function

Repeated Use Function

|

| |

| |

|

The program SML is a joint development of the Swiss Federal Food Safety and Veterinary Office

(FSVO, Switzerland), the company Advanced Kinetics and Technology Solutions AG (AKTS AG, Switzerland) and

MDCTec Systems GmbH (Germany). It supports compliance and migration risk assessment with European and Swiss Legislation

for materials coming into contact with food, cosmetics, pharmaceuticals or drinking water. The verification of compliance

with specific migration limits (SML) of food contacting materials and articles by the application of generally recognized

diffusion models is included in the European legislation since more than 10 years.

|

| |

| |

Safety evaluation of plastics materials and articles with respect to other applications like toys,

automotive, construction, etc. is supported as well.

|

|

| |

|

Improved Ergonomy

|

|

Besides the new functionalities, AKTS-SML version 6 includes a new ribbon menu which significantly

improves the global software ergonomics and ease of access to its different tools.

|

|

| |

|

| |

|

Repeated Use Function - Application Note

|

| |

| Demonstration Video |

|

|

| |

| Description |

Single- and repeated use food contact materials such as food packaging and kitchen utensils,

drinking bottles, food processing equipment, are in focus of the food contact legislation.

Generally, migration of the packing components into food, which is determined by the rate of the diffusion, will be reduced upon

successive uses. However, in specific cases the migration may increase upon successive uses due to e.g. the hydrolysis as observed

in the case of the migration of formaldehyde from articles produced from phenol-formaldehyde or melamine-formaldehyde resins.

Therefore, migration from repeated use articles e.g. a food storage boxes, bowls or plates should be assessed in three successive

contact periods, using a new portion of food simulant for each contact period. Conventionally the migration rate found determined

in the third migration experiments shall comply with the relevant specific migration limit.

Determination of the migration from a repeated use article is similar to the procedure applied for single use articles. However,

establishing the right contact conditions of time and temperature as well as the actual surface to volume ratio may be more complex.

More details can be found in the guidelines of the EU Commission and the Joint Research Center:

|

|

|

More complex procedures should be applied for plastic materials which are in contact with drinking water.

In this case, the simulation of the migration rate has to follow the testing requirements given in DIN EN 12873-1 and 2 and the

KTW Guideline of the German UBA:

|

| |

|

cold water: 1 + 3 x 3 days

|

| |

|

warm water: 1 + 3 x 1 + 3 + 3 x 1 days

|

| |

|

hot water: 1 + 3 x 1 + 3 + 3 x 1 days

|

|

According to the above requirements the extended testing cycles up to 31 days by repeating the

above 10 days-long test cycles are optional for single- but compulsory for multilayer materials.

The above-mentioned test cycles are implemented as predefined cycles in the SML 6 software:

|

|

|

Predefined cycles in the Predictions window

|

|

or can be customized by user by e.g. extending of testing scheme for 31 days = 4 x (4 x 1 + 3) + 3 x 1 d

|

|

|

Set up of an advanced repeated use function

|

| |

| Example |

|

The application of the the repeated use function implemented in the SML 6 software is

illustrated for the composite drinking water pipe with the layered structure HDPE/Aluminium/PE-Xb:

|

|

|

Composite drinking water pipe

|

|

It is assumed that the adhesive layer between the plastic (HDPE and PE-Xb) and the

aluminium layers contains a migrant which is the residual amount of 5000 ppm maleic acid.

|

|

| |

| Repeated use simulation |

|

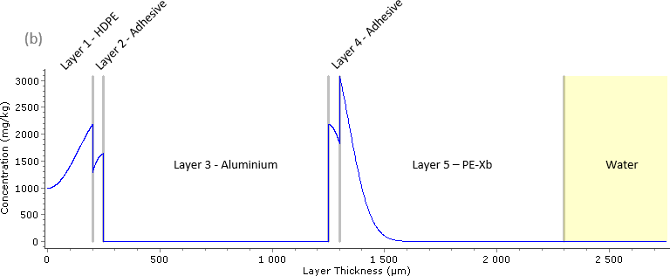

The migration simulations during the contact of the pipe with cold (23°C) and warm water (60°C)

were carried out according to the specific migration assessment requirement of the KTW Guideline. The figure (a) presents the

initial spatial concentration profile C(x,t) of the migrant (maleic acid) at 23°C. The figure below (b) shows the spatial concentration of the migrant

(maleic acid) C(x,t) after a period of 10 days at 23°C.

|

|

|

Initial spatial concentration profile C(x,t) of the migrant (maleic acid), essentially contained in the two adhesive layers

|

| |

|

|

Spatial concentration profile C(x,t) of the migrant (maleic acid) after 10 days at 23°C

|

At 23°C the PE-Xb layer acts as a functional barrier and no migration of maleic acid from the pipe

to drinking water is observed after 10 days. The migrant concentration profile C(x,t) in figure (b) clearly confirms that the maleic acid present in the adhesive

layer penetrates only slightly through the PE-Xb layer. The same result, i.e. no migration of maleic acid from the pipe to drinking water

is observed for the extended test cycle of 31 days.

The following figures shows the migration of maleic acid from the pipe to drinking water during 35 days at 60°C

(test applied for the warm water: 1 + 3 x 1 + 3 + 3 x 1 days): the figure (a) presents the initial spatial concentration profile C(x,t) of the migrant (maleic acid),

the figure (b) shows the spatial concentration of migrant C(x,t) in the

pipe after 35 days, figure (c) presents the concentration of maleic acid C(t) in water as a function of time.

|

|

|

Initial spatial concentration profile C(x,t) of the migrant (maleic acid), contained in the two adhesive layers

|

| |

|

|

Spatial concentration profile C(x,t) of the migrant (maleic acid) after 35 days at 60°C

|

| |

|

|

Concentration of the migrant (maleic acid) C(t) in water as a function of time

|

| |

|

The estimated amount of maleic acid migration from the pipe to drinking water is 1.718 mg/l as presented in figure (c) and in the table below.

|

|

|

The migration simulation was performed under "realistic" conditions, i.e. mean AP-value

(polymer specific constant used to estimate the diffusion coefficients) of the distribution was used, therefore it can be expected

that the estimated result is close to an experimental result obtained under the same testing conditions.

|

|

|

| |

Yours sincerely,

AKTS AG

|

Click here to contact us

Click here to contact us

Forward to a colleague

Forward to a colleague

|

AKTS AG

Advanced Kinetics

& Technology Solutions

TECHNOArk 1

3960 Siders

Switzerland

|